SAMKOREA Luster Sheet – Flexible Edge-Lit Light Panel Film for LED Signage, Acrylic Board, Backlit D

-

Payment

L/C(sight) , T/T

-

MOQ

3 ea

-

Supply Ability

100 ea per Weekly

-

Supply Details

Customization

-

Country of sale

Americas, Europe, Africa

-

PRICE

-

EXW

USD 610.00

(1 ea)

-

ITEM SPECIFICS

-

Brand

Model NEOSHEETLuster Sheet

-

origin

Republic of Korea

-

Size(Capacity)

Maximum Width1.22m, Roll Length Up to 50m

-

Material

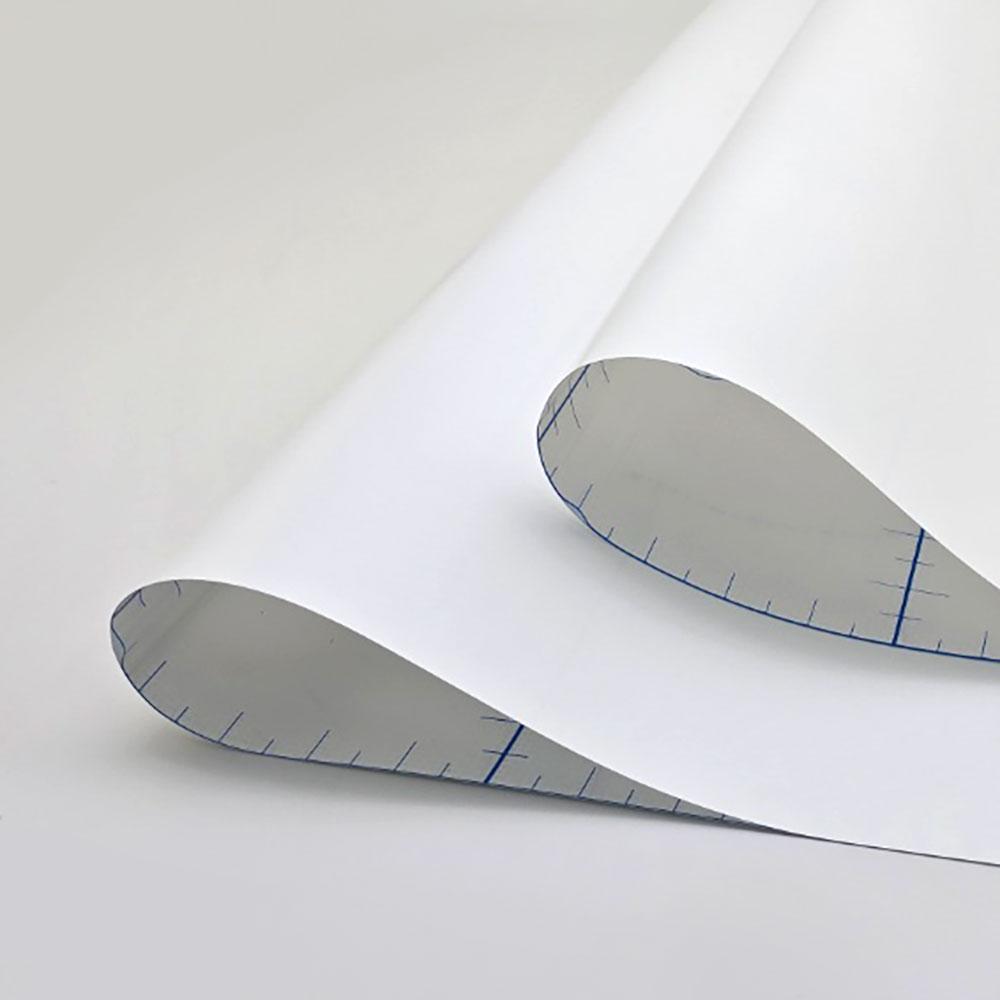

PET + Fluorescent Adhesive Pattern + Reflective Sheet + Release Film

-

Weight

15kg

-

Color

Whight

-

Function

Light guide plate film

-

Style

Roll

PRODUCT DESCRIPTION

Luster Sheet is an innovative high-efficiency surface light diffusion film optimized for edge-lit LED panel lighting. This patented material features a special fluorescent adhesive pattern printed on a PP x-layer, laminated over a PET release liner. It is designed for easy application directly onto transparent acrylic panels, eliminating the need for conventional light guide plate (LGP) laser processing.

When LEDs are installed along the edge of the acrylic, the Luster Sheet enables uniform and glare-free illumination across the entire surface. This edge-lighting method significantly reduces energy consumption compared to direct-lighting systems, making it ideal for eco-conscious lighting solutions.

Thanks to its excellent light uniformity and flexible design capabilities, the Luster Sheet can be precision-cut into any shape or logo using sheet-cutting methods—without obstructing the view, making it a perfect fit for transparent window signage. It’s an ideal choice for store windows, indoor signs, and advertising displays where both aesthetics and energy efficiency matter.

When LEDs are installed along the edge of the acrylic, the Luster Sheet enables uniform and glare-free illumination across the entire surface. This edge-lighting method significantly reduces energy consumption compared to direct-lighting systems, making it ideal for eco-conscious lighting solutions.

Thanks to its excellent light uniformity and flexible design capabilities, the Luster Sheet can be precision-cut into any shape or logo using sheet-cutting methods—without obstructing the view, making it a perfect fit for transparent window signage. It’s an ideal choice for store windows, indoor signs, and advertising displays where both aesthetics and energy efficiency matter.

1. It is a patented cotton light-emitting light guide plate film sheet.

2. Uniform surface light emission and high efficiency solution that does not require light guide plate processing

• Like conventional light guide plates, uniform surface light emission can be implemented without V-CUT and actual dot printing.

• It is a structure printed with a fluorescent adhesive pattern on the PET film, which adheres to transparent acrylic and enables uniform surface light emission by LED irradiation.

• Like conventional light guide plates, uniform surface light emission can be implemented without V-CUT and actual dot printing.

• It is a structure printed with a fluorescent adhesive pattern on the PET film, which adheres to transparent acrylic and enables uniform surface light emission by LED irradiation.

3. Edge (Side) Lighting Method → Maximize Energy Savings

• For general LED signage lighting, multiple LEDs should be arranged (vertical type) in the area,

The cluster seat can secure sufficient amount of light with only a few LEDs attached to the two sides of the side (edge).

• As a result, you can reduce power consumption by up to 40 to 60%, as well as heat and maintenance costs.

• For general LED signage lighting, multiple LEDs should be arranged (vertical type) in the area,

The cluster seat can secure sufficient amount of light with only a few LEDs attached to the two sides of the side (edge).

• As a result, you can reduce power consumption by up to 40 to 60%, as well as heat and maintenance costs.

4. Sheet Cutable (Free Light-Emitting Design) for Partial Light → Maximize Energy Savings

• The general light guide plate has a basic surface light emission, but the cluster sheet is free to cut, so only the necessary parts can be emitted, which can save energy.

For example, text, logo, illustration figure, etc. can be cut and attached to the desired shape

You can apply unique light-emitting designs to window signs, glass show windows, exhibition booths, and more.

• The general light guide plate has a basic surface light emission, but the cluster sheet is free to cut, so only the necessary parts can be emitted, which can save energy.

For example, text, logo, illustration figure, etc. can be cut and attached to the desired shape

You can apply unique light-emitting designs to window signs, glass show windows, exhibition booths, and more.

5. It guarantees excellent durability.

• Excitation due to weakening of adhesion (blackening), fabric tearing due to ultraviolet (UV) rays, and light darker as it moves away from the light source

• Excitation due to weakening of adhesion (blackening), fabric tearing due to ultraviolet (UV) rays, and light darker as it moves away from the light source

6. possessing specialized manufacturing technology

• Secure advanced productivity such as customization (copper plate design), roll to roll (R2R) production, sheet cutting, packaging, etc

• Secure advanced productivity such as customization (copper plate design), roll to roll (R2R) production, sheet cutting, packaging, etc

7. a wide range of applications

• Window-type signboards, indoor and outdoor signboards, exhibition booths, corporate promotional materials,

LED art walls, cafe interiors, architectural lighting, retail stores, etc

It has a very wide range of applications, so it can be used throughout the interior and advertising industries.

• Window-type signboards, indoor and outdoor signboards, exhibition booths, corporate promotional materials,

LED art walls, cafe interiors, architectural lighting, retail stores, etc

It has a very wide range of applications, so it can be used throughout the interior and advertising industries.

R&D CERTIFICATE

-

- CERTIFICATE OF PRODUCT-SPECIFIC APPROVED EXPORTER

- Korea FTA

- 20250326

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Telegraphic Transfer : T/T

- Name : JIWON KANG

SHIPPING

Shipping from :

Republic of Korea

- 37 Chilbongsan-ro 337beon-gil, Yangju-si, Gyeonggi-do (11447)

Sam Korea Inc.

The person in charge

SANGHYEON YOOAddress

37 Chilbongsan-ro 337beon-gil, Yangju-si, Gyeonggi-do (11447)

QR

Sam Korea Inc.

Introduction

Sam Korea Co., Ltd. – A New Standard in Energy-Saving Lighting

Sam Korea Co., Ltd. is a specialized manufacturer of high-efficiency lighting materials, particularly Luster Sheet, a revolutionary edge-lit light-diffusing film designed for LED applications.

With proprietary adhesive pattern printing technology, the Luster Sheet enables uniform surface illumination simply by attaching it to a transparent acrylic panel—no additional light guide plate (LGP) processing is needed. This innovative solution drastically reduces the number of required LEDs while maintaining brightness, leading to significant energy savings.

Luster Sheets can be freely cut into various shapes and designs, making them ideal for signage, interior lighting, display booths, and creative lighting solutions. Backed by extensive experience in gravure printing, roll-to-roll processing, and lamination, Sam Korea also offers customized OEM and ODM solutions.

Main Products:

• Luster Sheet

• Edge-lit panel lighting film

• Custom-cut illumination designs

Applications:

• Signage and advertising

• Interior and architectural lighting

• Exhibition and window display panels

• LED signboards, exit/emergency lights, and smart displays

Sam Korea is committed to delivering sustainable, high-quality lighting solutions to clients worldwide.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Luster Sheet Edgelit Surface Light Film for LED Panels LGP Alternative

-

- Established :

- 2017-06-14

-

- Total Annual Revenue :

- 3~5 million (KRW)

-

- Total Employees :

- 5~10 people

R&D CERTIFICATE

-

- CERTIFICATE OF PRODUCT-SPECIFIC APPROVED EXPORTER

- Korea FTA

- 20250326

- 인증서보기

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~5 million (KRW)

-

- Total export revenue (previous year in USD)

- 8,000

-

- Number of foreign trade employees

- 5~10 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- Sam Korea Inc. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★

SUPPLIER BEST

- No Items